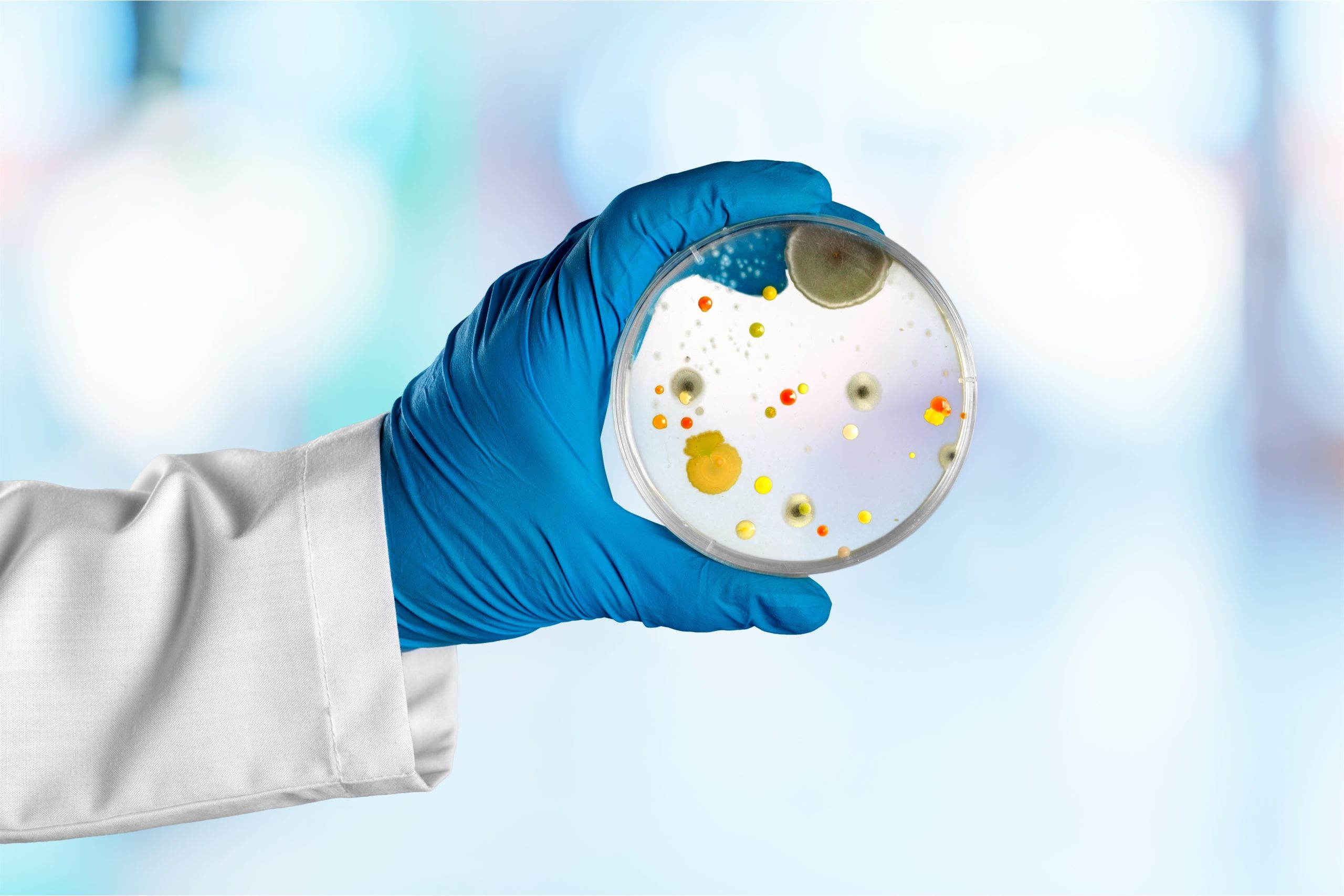

Antimicrobial effectiveness testing involves introducing a specified number of certain microorganisms, such as bacteria, yeasts, and molds, into the product to assess its ability to prevent contamination and growth of microorganisms. This testing is also referred to as preservative efficacy testing or challenge testing. It plays a vital role in industries including pharmaceuticals, cosmetics, personal care products, and food and beverages, as it ensures product safety and stability by identifying potential microbial contamination. To determine the antimicrobial effectiveness and establish limits for microbial contamination in non-sterile products, the widely used USP testing follows pharmacopoeia standards. At Chromak Research, our experts conduct Antimicrobial effectiveness testing in adherence to the stringent guidelines and procedures outlined in USP .

Importance of Antimicrobial effectiveness testing

Non-sterile products that contain multiple dosages, such as hand sanitizers, lotions, and cosmetics, may necessitate antimicrobial effectiveness testing. This testing serves to showcase the efficacy of the preservative system within the product. Antimicrobial effectiveness testing is crucial in ensuring the safety of non-sterile products for their intended use and consumption. The USP antimicrobial testing evaluates the ability of antimicrobial agents to prevent microbial growth. All injectable products packaged in multidose containers must exhibit antimicrobial effectiveness, regardless of whether the antimicrobial activity is inherent in the product formulation or added through a known antimicrobial agent. Aqueous based, multidose topical and oral formulations must also demonstrate antimicrobial effectiveness. Additionally, ophthalmic, otic, nasal, irrigating, and dialysis fluids necessitate antimicrobial activity.

Testing of Products

USP is formulated to assess the antimicrobial effectiveness of the medication by introducing high quantities of microorganisms into the preserved compounded mixture to mimic a potential contamination incident during or post compounding. The preserved drug product and microorganisms are combined and monitored for colony forming units (CFUs) as they incubate over a period of time.

The added microorganisms include:

• Candida albicans

• Aspergillus brasiliensis

• Escherichia coli

• Pseudomonas aeruginosa

• Staphylococcus aureus

The CFUs are counted at different time points based on the specific category defined by USP that applies to the tested product. The purpose of conducting periodic plating is to showcase the product’s capability in managing microbial growth throughout time.

| Categories | Product description |

|---|---|

| 1 | Injections, other parenteral including emulsions, otic products, sterile nasal products and ophthalmic products made with aqueous bases or vehicles |

| 2 | Topically used products made with aqueous bases or vehicles, nonsterile nasal products and emulsions, including those applied to mucous membranes |

| 3 | Oral products other than antacids, made with aqueous bases or vehicles |

| 4 | Antacids made with an aqueous base |

Criteria for Antimicrobial effectiveness

The criteria for determining the adequacy of preservation of a drug product is also outlined in USP, taking into account the drug category and the specific type of microorganism.

| For Category 1

Products |

Bacteria | Not less than 1.0 log reduction from the initial calculated count at 7 days, not less than 3.0 log reduction from the initial count at 14 days, and no increase from the 14 days count at 28 days. |

| Yeast and molds | No increase from the initial calculated count at 7, 14 and 28 days. | |

| For Category 2

Products |

Bacteria | Not less than 2.0 log reduction from the initial count at 14 days, and no increase from the 14 days count at 28 days. |

| Yeast and molds | No increase from the initial calculated count at 14 and 28 days. | |

| For Category 3

Products |

Bacteria | Not less than 1.0 log reduction from the initial count at 14 days, and no increase from the 14 days count at 28 days. |

| Yeast and molds | No increase from the initial calculated count at 14 and 28 days. | |

| For Category 4

Products |

Bacteria, Yeast and molds | No increase from the initial calculated count at 14 and 28 days. |

To obtain a passing result, all criteria listed in above Table must be met for the applicable drug product category.

Chromak Research has fully equipped state of the art laboratory facilities and various techniques with ISO 9001:2015 and ISO/IEC 17025:2017. Our extensive network of testing facilities across the globe allows us to conduct thorough tests, helping you mitigate risks, expedite time to market, and assess the quality, safety, and performance of your products in compliance with relevant health, safety, and regulatory standards